BURNER SERVICES

Marine burner service – From inspection to installation

Scandinavian Boiler Service provides the full range of services for all makes of marine burners and control & combustion systems. Our automation specialists perform inspections, troubleshooting, maintenance, service, upgrades, conversions, installations, and personnel training. Moreover, SBS offers tailor-made solutions for regular inspections, pre-docking inspections, and maintenance service agreements with a focus on optimizing the burner and control system operation. All jobs are completed with thorough instruction of the personnel together with a full report containing a description of the work executed, the condition of the heating system, and advice for maintenance.

Engineering and redesign

Our engineering division excels in preparing for larger upgrades and conversions. Design, calculations, and modification drawings are conducted by our experienced engineers to ensure smooth execution procedures.

Multi-brand expertise

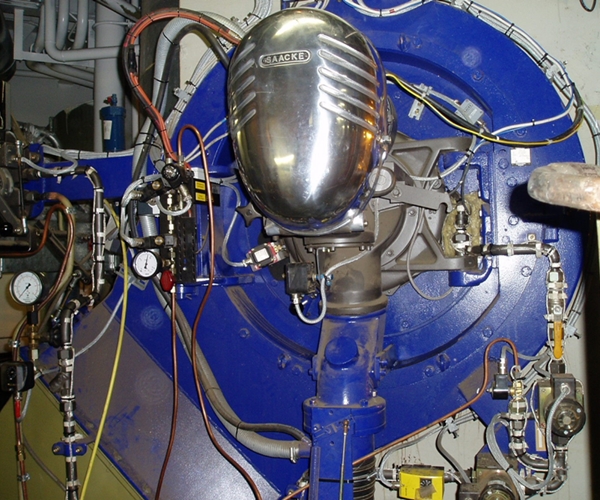

SBS is the proud authorized service, sales, and spare parts agent for Saacke, Petro, Oilon, Weishaupt, and Sunflame in several markets. Additionally, we provide service and support on all makes of burners such as Volcano, Vesta KB, Hamworthy, etc.

OUR SERVICES

Keeping our clients operational 24/7 is of our utmost importance! With SBS 24-hour services, we assist all our customers from our strategically located service centers around the world with burner and automation challenges, upgrades, or retrofit projects. Ensuring smooth sailing for all our customers’ ships is our top priority! Our wide range of services below ensures that no ship is left behind.

BURNER SERVICES

SBS has a complete range of burner services from standard to customized solutions for projects of all sizes and requirements. Explore our range of services and get in touch with us for your burner services needs today.

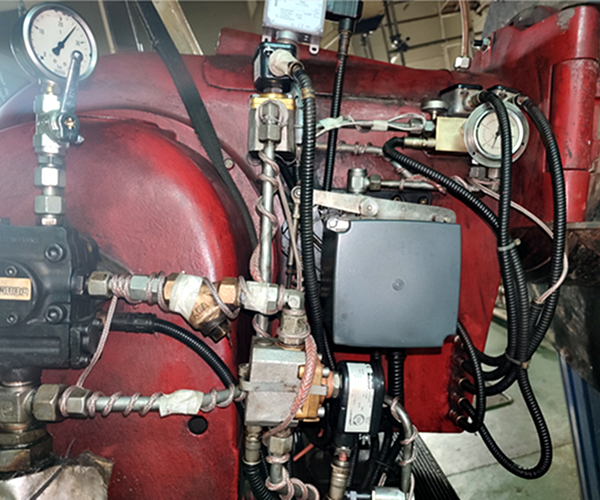

Combustion Systems

Our Service Engineers have experience with different types of combustion. We can offer Service for combustion adjustment on the Steam atomizing, Rotary cup atomizing, and Pressure atomizing burners. We are familiar with burners such as Saacke, Volcano, Petro, Weishaupt, Oilon, Aalborg, Sunflame, Hamworthy & others.

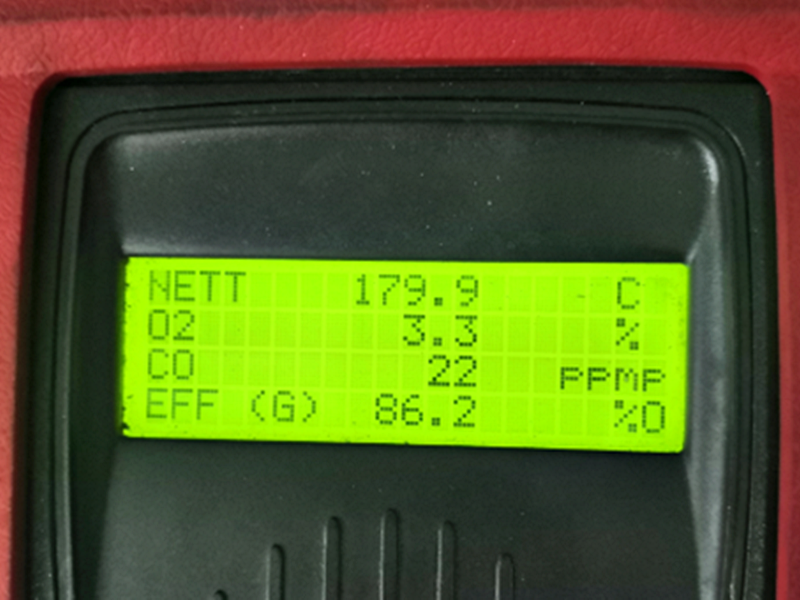

Our team is determined to ensure optimal combustion, so our customers can benefit from our services. We also believe that with optimal combustion we can contribute to the lowering of CO2 & other emissions, as part of our contribution to the protection of our planet ecosystem.

Our team is equipped with special flue gas analyzing instruments that ensure fast sampling and accurate measuring, also our teams are equipped with special software needed for some type of combustion systems. All of this ensures fast adjustment and lowers costs by reducing the time needed to perform service.

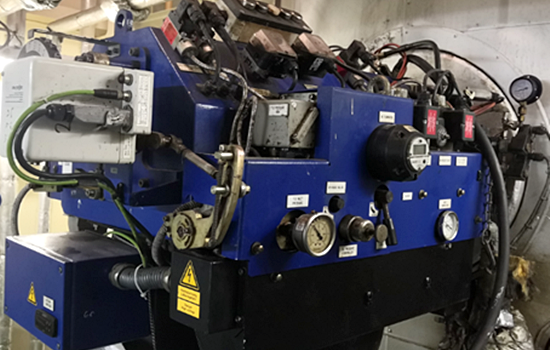

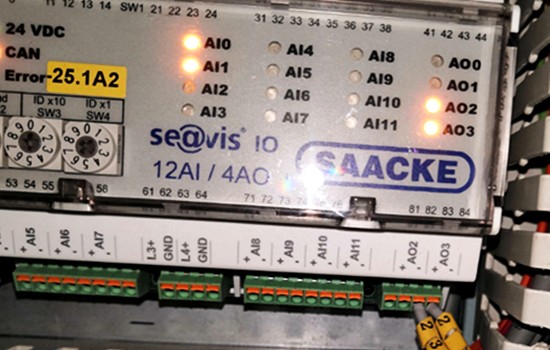

Automation Service

Our Service Engineers are equipped with special tools and instruments ensuring accurate measuring and calibration of the equipment. Also, they have a range of software needed to speed up troubleshooting and ensure a quick evaluation of the problem at hands.

With the support of our Spare parts department in Denmark, we ensure fast delivery of the spare parts when needed. In addition, we have ready stock of key equipment that requires a longer delivery time, such as far east manufactures, to service any immediate needs of our customers.

SBS worldwide offices and network ensures that our customers are always attended to worldwide. Even if the vessel was attended to in Europe and required some spare parts when docking in the USA, SBS is able to make the necessary arrangements and have the spare parts ready for servicing when the vessel docks at the port in the USA. To lower the traveling costs, SBS is also able to deploy our Service Engineer in the USA office to the vessel for assistance.

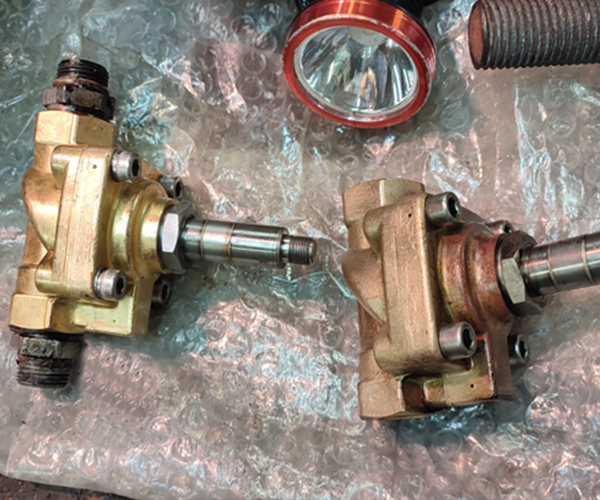

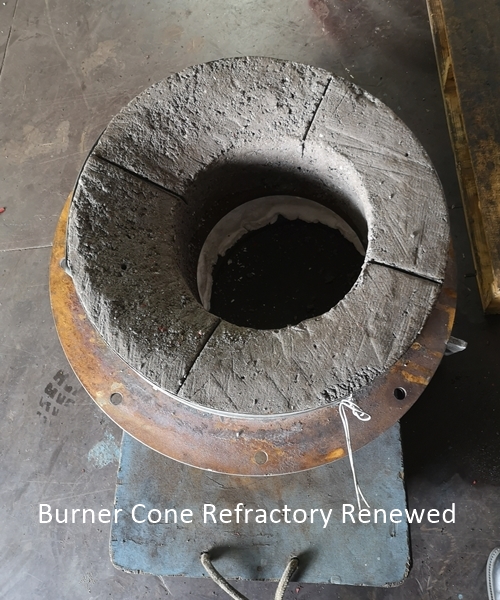

Burners overhaul

Our Service Engineers have experience and special tools for making overhauls of the rotary cup burners. This ensures our customers that we can periodical check and overhaul burner to prevent failure, this we suggest to make periodically during dry docking so our customers are sure that for next few year they not have complex problems with burner.

Beside this we can also overhaul Main Fuel Oil Valves with Repair kits which is very important to take care off because with much more MGO operations it is crucial to prevent leakage of the MGO in the furnace, to prevent possible explosion.

We can overhaul Compound regulators also with repair kits from the manufactures. We can also provide overhaul & calibration of the automation equipment like delta P transmitters for combustion process, positioners, pressure transmitters, thermo couples & others. We can check different type of the control equipment like controllers, PLC, Timers.

LSGO CONVERSIONS

SBS offer solutions to upgrade of burners and fuel lines enabling them to comply with 2005/33/EU, CARB and IMO ECA requirements. Based on our customers’ individual requirements and preferences, SBS are able to provide solutions for most marine boilers. We cooperate with most burner makers, but are also able to provide our own engineered solutions. Modifications on fuel lines are always subject to class approval, wherefore the change-over is not only a technical matter, but requires solution approval and survey of the installation.

SBS is capable of modifications ranging from simple component replacement to re-engineering of control systems, design of new atomizers and installation of complete new fuel lines.

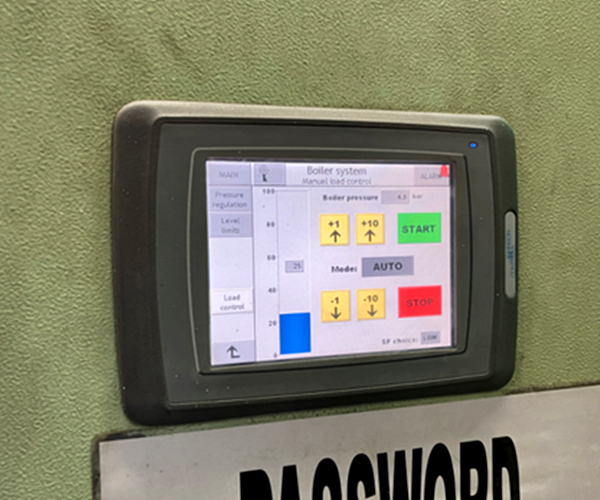

LSGO boiler upgrades hatch SBS retrofit boiler control systems

The large number of LSGO upgrades conducted by SBS on a very wide variety of boiler systems has lead to the development of a dedicated load control upgrade capable of handling multiple fuel combustion parameters and automatic switching between fuels. The heart of this next generation upgrade, the Feed-back Manipulation Unit (FMU), comes as a separate control panel for easy installation; it includes a graphical touch screen display and is designed specifically for large steam atomizing burners. The installation of the of FMU-based upgrades with special designed atomizers has been very successful and so far almost 100 FMU-solution are installed on large tankers and many of them already commissioned and approved by the classification societies.

The variety of applications, with different burner makes (Aalborg, Hamworthy, Volcano, Saacke), one or two boilers and up to three burners per boiler, has led to a very versatile design, actually capable of taking over the complete load control function of the boiler control system. This has also solved another pressing issue, as many older vessels are facing problems with the maintenance and spare parts for obsolete boiler control systems.

In the merchant fleet there is large number of combustion control systems for which production of spare parts and complete units has stopped, and also there are many of the PLC based BMS systems for which spare parts are not available any more. With the combination of the proven FMU load controller and the new universal SBS BMS (Boiler Management System) & SBS ACC (Automatic Combustion Controller), a complete, affordable and reliable “off the shelf” retrofit solution will become available during 2011, not only for steam atomizing burners, but for all types of modulating burner systems.

The workflow

SBS works with a 6-steps model to keep focus on the process and provide customers a general overview of the options and scope of work:

Input data list of boiler, burner, fuel pumps, and ship’s schedule.

Thorough Inspection of Burner and Fuel System

When the ship operators are in doubt of the marine boiler systems’ compatibility when comes to continuous Gas Oil operation, SBS is able to offer systems inspections to identify possible hazards and to analyze the suitability for Gas Oil operation for all components. During inspections, the general fuel oil system layout and design will be evaluated, and the most cost-effective way of modification will be proposed to ensure that the Gas Oil operation is carried out at its maximum capacity. For series of new buildings, normally only one vessel needs to be inspected in order to identify the necessary steps.

Calculations and Modification Drawings

Based on the results of the inspections, SBS will provide the suggested calculations and modification drawings for the existing fuel oil piping and electrical cabling. This can include design revisions for the existing boiler controls regardless of the origin of the controls. With the vast experiences and expertise gained from more than 1000s of land-based Gas Oil boiler plants projects, we are confident of providing complete solutions to all our customers.

Turnkey Solution including Parts and Implementation Plan

From our vast pool of resources for Gas Oil firing and supply equipment, SBS is able to provide the component required for any necessary modifications. If any components need to be exchanged or a complete redesign of the system is required, we can provide either the components or offer turnkey solutions for consideration. Our standardized Gas Oil firing upgrade equipment includes simple replacement components to new redundant Gas Oil supply systems. However, the degree of solutions provided is dependent on the existing system layout and operating profile.

Upgrade Completion & Instruction for Ship’s Crew

Our proposed solutions can be applied by the crew of the ship during sailing or by a shipyard during dry-docking. For all kinds of modifications, we can provide full turnkey installations while sailing from one port to another with the auxiliary boiler(s) shut down while the vessel is running on exhaust gas boiler(s) only. The necessary burner re-adjustment after such a modification can be carried out by any of our service stations worldwide. With our range of Gas Oil operation upgrades, our customers are spoilt for choices to select an upgrade suited for their needs.

Approval by Classification Authority.

Steam atomizing burner

Required modification of Burner/control system

New atomizer for dual fuel operation, air flow and lance upgrade, automatic hook up box to be installer, F/A ratio on MGO to be celibrated.

Recommendation for burner

Test flame pick up on MGO and replace non-responding and IR-type flame sensors.

Fuel supply system and change over automation

Install new MGO fuel line with automatic change over. Alternatively the existing line can be modified to operate on MGO, but this is not recommended unless space does allow for a new line.

Rotary cup burner

Required modification of Burner/control system

Adjust oil pressure.

Recommendation for burner

Test flame pick up on MGO and replace non-responding and IR-type flame sensors. for burners used for inert gas generation, a load control modification is required.

Fuel supply system and change over automation

Install new MGO fuel line with automatic change over. Alternatively the existing line can be modified to operate on MGO, but this is not recommended unless space does allow for a new line.

Pressure jet burner

Required modification of Burner/control system

Pressure jet burner

Required modification of Burner/control system

Carry an extra fuel pump as onboard spare, adjust oil pressure.

Recommendation for burner

Change from two nozzle to single nozzle for on/off control systems, add new pressure switch and additional flame sensor.

Fuel supply system and change over automation

Where possible substitute DO with MGO and replace booster pump with one compatible with MGO, ensure shut down/by-pass of heating sources by automation upgrade. Alternatively install new MGO line with automatic change over.

Rotary cup burner

Required modification of Burner/control system

Adjust oil pressure.

Recommendation for burner

Test flame pick up on MGO and replace non-responding and IR-type flame sensors, double soleniod valves to be fitted in place of single.

Fuel supply system and change over automation

Where possible substitute DO with MGO and replace booster pump with one compatible with MGO, ensure shut down/by-pass of heating sources by automation upgrade. Alternatively install new MGO line with automatic change over.

Steam atomizing burner

Required modification of Burner/control system

New automizer for MGO, load control upgrade-either software upgrade for pressure control or hardware for flow control system to be added. Automatic mode detection switches to be installed, and F/A ratio on MGO to be calibrated.

Recommendation for burner

Test flame pick up on MGO and replace non-responding and IR-type flame sensors.

Fuel supply system and change over automation

Install new MGO fuel line with automatic change over. Alternatively the existing line can be modified to operate on MGO, but this is not recommended unless space does allow for a new line.

Rotary cup burner

Required modification of Burner/control system

Adjust oil pressure.

Recommendation for burner

Test flame pick up on MGO and replace non-responding and IR-type flame sensors. for burners used for inert gas generation, a load control modification is required.

Fuel supply system and change over automation

Install new MGO fuel line with automatic change over. Alternatively the existing line can be modified to operate on MGO, but this is not recommended unless space does allow for a new line.

Steam atomizing burner

Required modification of Burner/control system

Load control modification with external signal processing unit, adjustment of post purge timer. Recommission on MGO.

Recommendation for burner

Test flame pick up on MGO and replace non-responding and IR-type flame sensors.

Fuel supply system and change over automation

Install new MGO fuel line with automatic change over. Alternatively the existing line can be modified to operate on MGO, but this is not recommended unless space does allow for a new line.

Rotary cup burner

Required modification of Burner/control system

Adjust oil pressure.

Recommendation for burner

Test flame pick up on MGO and replace non-responding and IR-type flame sensors. for burners used for inert gas generation, a load control modification is required.

Fuel supply system and change over automation

Install new MGO fuel line with automatic change over. Alternatively the existing line can be modified to operate on MGO, but this is not recommended unless space does allow for a new line.

Pressure jet burner

Required modification of Burner/control system

Carry an extra fuel pump as onboard spare, adjust oil pressure.

Recommendation for burner

Test performance on MGO, adjust F/A ratio, possibly replace oil nozzle with larger model if output is too low. Test flame pick up on MGO and replace non-responding and IR-type flame sensors.

Fuel supply system and change over automation

Where possible substitute DO with MGO and replace booster pump with one compatible with MGO, ensure shut down/by-pass of heating sources by automation upgrade. Alternatively install new MGO line with automatic change over.

Pressure jet burner

Required modification of Burner/control system

Carry an extra fuel pump as onboard spare, adjust oil pressure.

Recommendation for burner

Test performance on MGO, adjust F/A ratio, possibly replace oil nozzle with larger model if output is too low. Test flame pick up on MGO and replace non-responding and IR-type flame sensors.

Fuel supply system and change over automation

Where possible substitute DO with MGO and replace booster pump with one compatible with MGO, ensure shut down/by-pass of heating sources by automation upgrade. Alternatively install new MGO line with automatic change over.

NEED BURNER SERVICE?

Need Burner services? Drop us a line and book the Burner services required for your ships.